If you’re planning a new expansion or reconfiguration project to increase your storage capacity, there’s a good chance that you’re using a selective pallet racking system in your warehouse. Selective pallet racking is the most economical way to store palletized products in a warehouse, especially for those with FIFO (First In First Out) accounting methods.

One of the most important things to consider when selecting the right equipment for your selective pallet racking system is the punching style of your beams and uprights. These punching styles can vary depending on the manufacturer. Because punching styles are dictated by your storage requirements, choosing the right type is critical when it comes to optimizing your warehouse and meeting OSHA safety requirements. Punching styles are also referred to as slot designs or beam connection slots.

The Industry Standard: Teardrop Rack Advantages

Teardrop rack is the current industry standard for punching styles on selective pallet racking. The term “teardrop” comes from the shape of the connection slots that are built into the pallet racking uprights.

Trial and error in material handling since the manufacturing boom post World War II eventually led warehouses to primarily use teardrop rack due to the teardrop slot design being simple and secure. Teardrop rack takes relatively less time to assemble and break down as your storage requirements change or your warehouse needs to be reconfigured for more space.

As palletized loads are placed on top of your rack, the load of the vertical supports is compressed into the bottom of the teardrop slot where the diameter is reduced, securely holding the horizontal beams into the pallet rack’s uprights. Therefore, the only way for a load to slip out of its positioning is to place an upward force on it. Basic physics keeps everything in place.

Quality teardrop rack beams also include pins that slide into the teardrop slot that have tight tolerances to ensure there is no slack when a load is placed on the beam. When used in conjunction with safety pins, the entire teardrop rack system becomes even more rigid and secure and can prevent common safety accidents caused by unintentional loosening or even forklift mishandling.

An important thing to consider when using teardrop racking is your load requirements. Always ensure that the load of the products is suitable for the load capacity of your teardrop pallet racking system.

The Benefits of Teardrop Racking

The benefits of teardrop rack are summarized below:

- Compatibility - Most teardrop rack uprights, beams, and accessories can be used interchangeably with other vendors, making it easier to shop for equipment. Note: It is important to triple-check the dimensions of your racking components if you are using different manufacturers’ beams. Even the smallest difference could reduce the structural integrity of your entire system.

- Security - Basic physics, along with the utilization of beam pins and safety clips, ensures that your rack system is strong and resistant to accidental unloading

- Ease of Use - Teardrop rack is easy to install and doesn’t require specialized skills or tools

- Flexibility - The standardization of the teardrop rack’s punching style allows warehouse managers to mix and match different uprights and beams to fit their storage needs

Other Common Punching Styles

Although decades of experimentation in the material handling industry pushed teardrop rack to become the most popularly used rack design in the modern era, other punching styles made their way to modern warehouse operations. The other major pallet rack slot designs that are commonly used are structural, speed rack, Ridg-U-Rack, and republic rack (sometimes called Keystone racking).

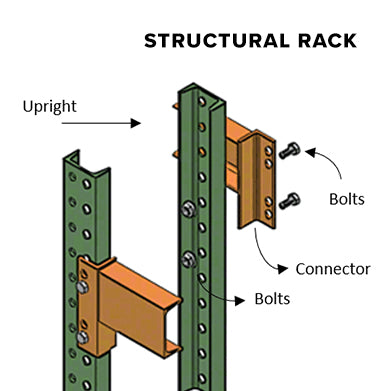

Structural rack

Structural rack designs use structural steel as the material for comprising the uprights and beams. Structural steel is well-known for its optimal strength-to-weight ratio. In a structural rack system, uprights and beams are connected by bolts (instead of pins and slots). The combination of the structural steel and bolted connections make structural rack a great system to use in warehouses where there are increased load requirements or if the rack is installed in harsh environments.

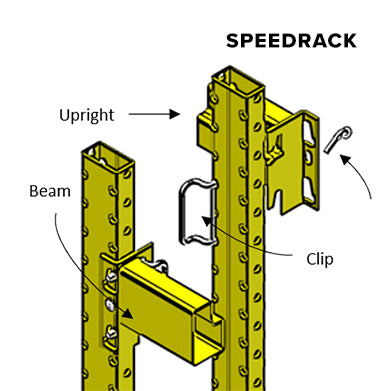

SpeedRack

SpeedRack is not a punching style per se - it is a pallet rack manufacturer brand that is based out of Michigan. Speedrack pallet racking uses a handle clip as well as J-hook safety pins to secure the rack together. The locking pins are the mechanism that secures the beam to the upright column, preventing accidental detachment from the uprights. The beams and uprights in a speedrack system use seamless tubular steel which allows for greater strength and higher resistance to damage versus open-shaped beams and columns. A Speed rack system can offer greater safety, longer life, and lower maintenance due to its construction, however, this comes at the expense of higher costs and lower product availability. Much like structural racking, speed rack is typically recommended for warehouse environments that have special requirements for handling palletized loads.

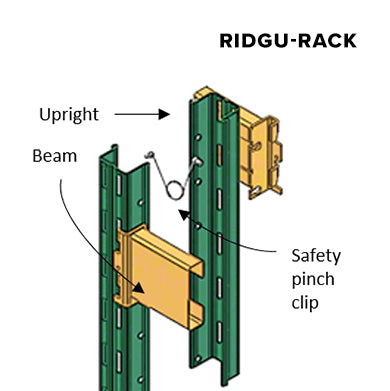

Ridg-U-Rack

Ridg-U-Rack is not a punching style per se - it is a pallet rack manufacturer brand that is based out of Pennsylvania. Ridg-U-Rack brand pallet racking is available in both slotted and teardrop style designs. The original Ridg-U-Rack designs were available only in slotted punching styles, but eventually, Ridg-U-Rack began to offer teardrop-style racking. Because of this, when referring to Ridg-U-Rack’s punching style is usually associated with the original slotted racking design.

Ridg-U-Rack’s slotted rack design offers greater vertical adjustability for beam heights. Slotted Ridg-U-Rack frames have 4” vertical adjustability versus teardrop rack which only allows half of that. The Ridg-U-Rack design uses safety pinch clips to secure the beam to the upright.

The original Ridg-U-Rack designs used to not include the beam connector plate in their measurements, meaning that a 96” beam was actually 96 ⅜”. This slight discrepancy could mean the difference between a fully interchangeable system and one that is not compatible with other racking. It is important to clarify this with your pallet racking provider before purchasing a Ridg-U-Rack system. Although the manufacturer eventually conformed to the industry standards, many older style products are still on the market, especially if you are buying used pallet racking.

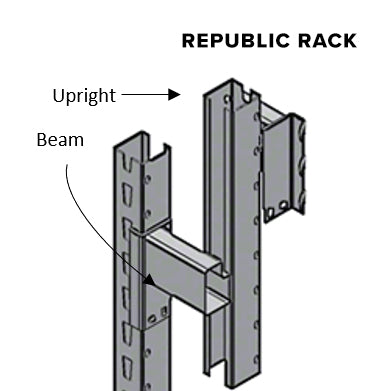

Republic Rack (or Keystone Rack)

Republic rack, also called keystone rack, uses keystone-shaped holes in the uprights. Republic rack is less commonly used nowadays, however, it is still used in many warehouses. The name “Republic” comes from the original manufacturer of keystone racking, Republic Storage Systems.

The differentiator for republic racking lies in the system’s locking mechanism. Republic racking uses square beam clip hooks versus the traditional round-shaped hooks, providing additional strength and safety. The additional strength provided by the attachment method is the main reason why republic rack gained popularity in previous years and is the reason why it still is used in modern warehouses.

Since republic racking is not as commonly used as teardrop racking, the same considerations apply when you are considering alternative styles to teardrop. Understanding the measurement profiles of the uprights and beams is key to building a scalable, working system. Factoring in your load requirements is also critical. Measurements and load capacities may vary from manufacturer to manufacturer, therefore if republic racking is something you are considering in your warehouse you should consult with your pallet racking provider to determine if this design style is right for your needs.

Is Teardrop Racking the Right Punching Style For My Warehouse?

Ultimately the choice to use teardrop rack versus the other types of selective pallet racking comes down to:

- Load requirements - If you have increased load requirements that exceed those of teardrop rack, using a different system like structural racking would help you meet those additional weight handling capabilities.

- Expandability requirements - Teardrop rack is the easiest to assemble or disassemble, making it a good choice for warehouses where reconfigurations are common. However, if you don’t foresee the need to rearrange your racking regularly and you need to take advantage of the upgraded load handling, the other styles of rack could be suitable for your needs.

- Warehouse environment - In harsh warehouse environments like those in cold storage or fast-paced distribution centers, sturdier racking systems like structural rack could be a better choice.

If you need assistance with determining your selective pallet racking requirements, don’t hesitate to reach out to us today. We offer warehouse design services to help you plan your next warehouse project.

Where Do I Buy Teardrop Racking?

American Storage & Logistics has a full inventory of in-stock teardrop racking uprights, beams, wire decking, starter bays, adder bars, and accessories like rack back safety panels, backstop beams, clips, post protectors, and more.

Our teardrop racking and accessories are available for same-day pickup or next-day delivery to areas close to Grand Rapids, Lansing, Battle Creek, and Kalamazoo. Visit our online shop to explore our teardrop racking and accessories or give us a call today at 616-246-8700 to place an order over the phone.